- +91 8329568782

- aglearningsolutions95@gmail.com

SAP S/4 HANA PP

SAP HANA Career Opportunities – Boost Your Career Growth with SAP HANA

SAP S/4 HANA PP Training Course In Pune

Overview of the SAP Production Planning (PP) module

SAP S/4HANA Production Planning (PP) is an essential module for manufacturing companies, providing comprehensive tools for planning and managing production processes. This module integrates deeply with other modules such as Materials Management (MM), Sales and Distribution (SD), Finance (FI), and Controlling (CO) to ensure end-to-end visibility and efficiency in the supply chain, from material procurement through production and delivery.

Key Sub-Modules and Features of SAP S/4HANA Production Planning (PP):

Material Requirements Planning (MRP)

MRP Live in S/4HANA offers real-time planning and faster processing, using the power of the HANA database.

Helps determine the material requirements for production based on current and forecasted demand, ensuring timely availability of materials.

Generates procurement proposals like planned orders and purchase requisitions automatically to optimize production and inventory.

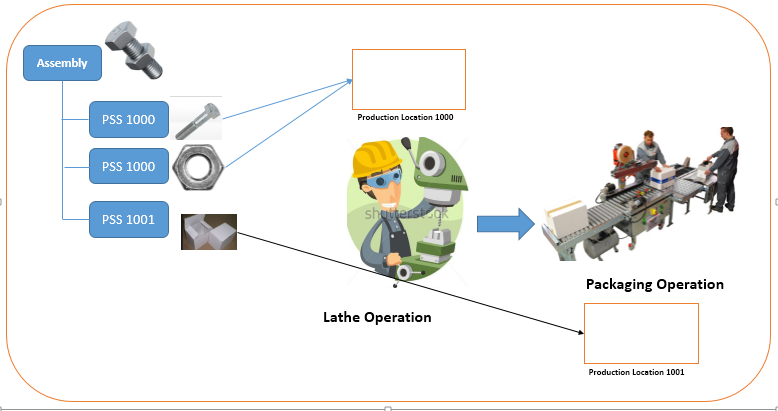

Bill Of Materials(BOM):

A BOM defines the list of components needed to produce a finished product or semi-finished product.

Supports multi-level BOMs, providing a detailed breakdown of materials used in the production process.

BOMs can be used for different purposes such as production, costing, and engineering.

Work Center:

Represents physical or logical units where production operations are carried out, such as machines, labor groups, or assembly lines.

Work centers contain information related to available capacity, scheduling, and costing.

Routings:

Define the sequence of operations needed to produce a product.Routings contain information about the work centers, operation times, and activities required for manufacturing.

Work Center:

Represents physical or logical units where production operations are carried out, such as machines, labor groups, or assembly lines.

Work centers contain information related to available capacity, scheduling, and costing.

Routings:

Define the sequence of operations needed to produce a product.Routings contain information about the work centers, operation times, and activities required for manufacturing.

Production Orders:

Central to the execution of manufacturing, Production Orders represent the actual work instructions for creating finished goods.

Production orders include details such as the materials required, operations to be performed, and resources allocated.

Allows for tracking of progress, recording of production confirmations, and capturing costs throughout the production cycle.

Demand Management:

Forecasts customer demand and acts as the input for MRP.

Combines planned independent requirements (e.g., based on forecasts) and sales orders to create a complete demand plan.

Helps balance demand and supply by generating production and procurement proposals.

Capacity Planning:

Manages the available capacity of resources (work centers, machines, labor) to ensure optimal production scheduling and resource utilization.

Detects capacity overloads and allows for capacity leveling through strategies like rescheduling or resource reallocation.

Production Scheduling:

Allows for detailed scheduling of production operations, considering factors such as lead times, resource availability, and priorities.

Advanced scheduling capabilities, like Finite Scheduling, ensure that planned production considers resource constraints for a realistic plan.

Shop Floor Control:

Manages the execution of production orders on the shop floor.

Enables order confirmations, recording actual time and materials consumed, and quality inspections as required.

Provides real-time insights into production progress, inventory changes, and production costs.

Repetitive Manufacturing (REM):

Designed for high-volume, continuous production processes.

Involves predefined production quantities for a specific period, using production versions and repetitive manufacturing profiles to streamline processes.

Process Industries (PP-PI):

Aimed at industries like chemicals, pharmaceuticals, and food and beverages, where batch-oriented production is required.

Master Recipes and Process Orders define the production process, which involves multiple process stages and resources.

Batch Management ensures precise tracking and traceability of batches throughout the production process.

Kanban:

Supports lean manufacturing and Just-In-Time (JIT) production principles using Kanban cards for signaling replenishment.

Reduces excess inventory, optimizes production efficiency, and helps maintain lean stock levels.

Integration with Quality Management (QM):

Ensures quality inspections during production to meet customer requirements and compliance standards.

Quality inspection results are integrated with production processes, influencing decisions such as rework or scrap.

Production Planning for External Procurement:

Advanced Planning and Scheduling (APS) capabilities are available for more complex production scenarios, integrating with SAP Integrated Business Planning (IBP) and SAP Advanced Planning and Optimization (APO) for comprehensive supply chain planning.

Key Benefits of SAP S/4HANA PP:

Real-Time Planning and Processing:

MRP Live leverages the in-memory computing power of SAP HANA, delivering faster and more accurate planning results.Real-time visibility into stock levels, production progress, and capacity utilization.

Improved Efficiency and Automation:

Automates production planning, order creation, and materials management, reducing manual effort and errors.

Streamlines communication and data flow across different functions, including production, procurement, and inventory.

Optimized Production Schedules:

Advanced scheduling capabilities ensure timely production while considering resource constraints.

Balances demand and supply to minimize stockouts and excess inventory.

Enhanced Quality Management:

Integrated Quality Management (QM) features ensure products meet specified quality standards during production.

Supports continuous improvement processes, reducing defects and rework.

Seamless Integration with Other Modules:

Tight integration with Materials Management (MM), Sales and Distribution (SD), Finance (FI), Controlling (CO), and Quality Management (QM) ensures a consistent and smooth flow of data.

Data consistency across modules eliminates duplication and provides comprehensive reporting capabilities.

Scalability and Flexibility:

S/4HANA PP supports various production processes, including discrete manufacturing, process manufacturing, and repetitive manufacturing.

Configurable settings and flexible master data management allow businesses to adapt to changing market demands.

Real-Time Analytics and Reporting:

Integration with SAP Fiori provides real-time analytics and role-based dashboards for production planners, managers, and shop floor operators.

Offers insights into key metrics such as production performance, capacity utilization, and order fulfillment status.

Lean Manufacturing Capabilities:

Supports Kanban, Just-In-Time (JIT), and other lean manufacturing principles to optimize processes and reduce waste.